Wildtype Salmon

Our first seafood

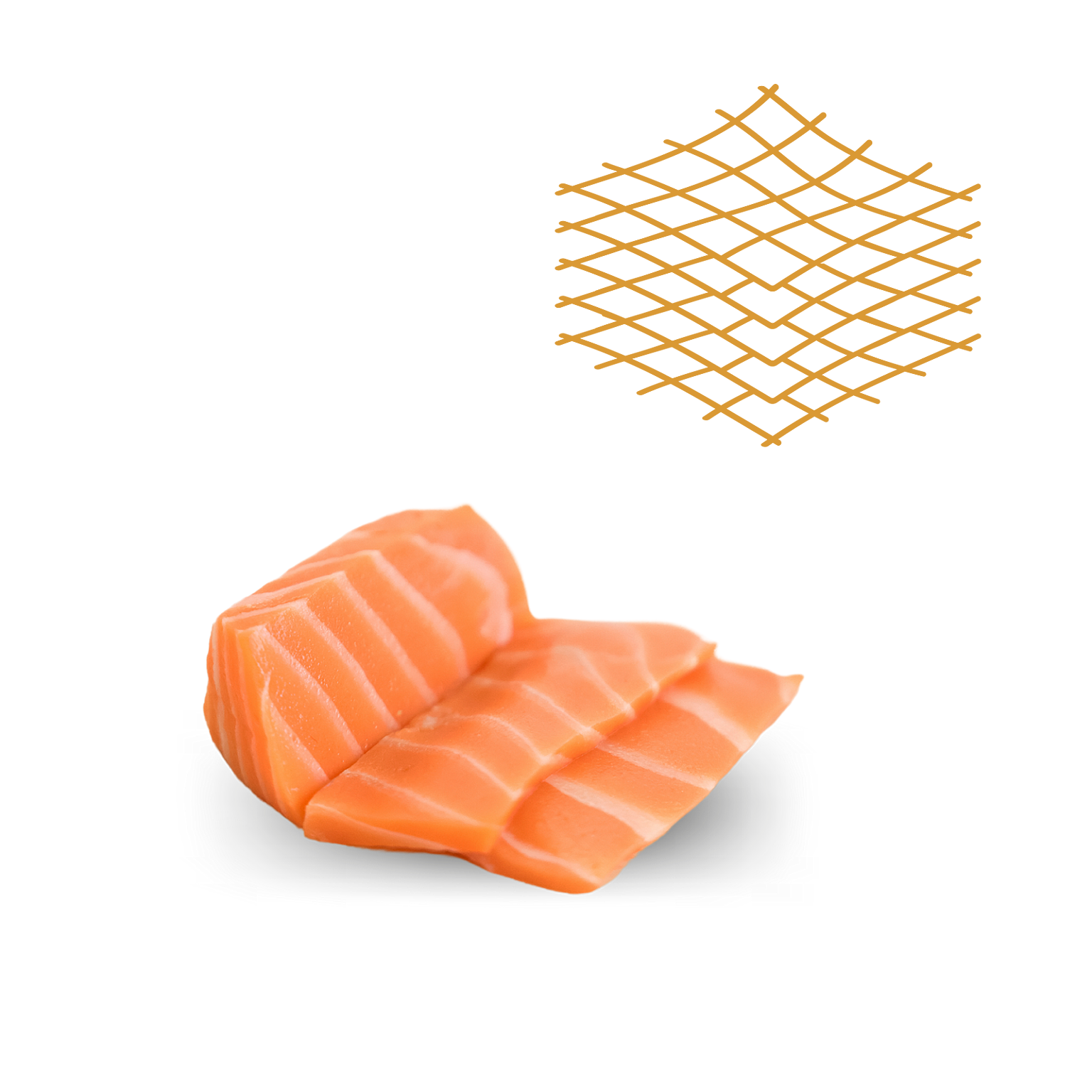

“Saku” is the Japanese term for a uniformly cut block of raw fish, perfect for slicing into sashimi. Wildtype salmon saku is the culmination of nearly a decade of research. The result is a cut of fish that's pure, flavorful, and kind to our seas.

Freshly made all year

Our saku is sushi-grade and is perfect for dishes like sushi, crudo, and ceviche. We made it for world-class chefs who seek out the delicate flavors of the best seafood.

Our Process

Wildtype salmon offers a choice beyond wild and farmed fish. It’s a chance to enjoy the seafood we love without sacrificing our food ideals.

01

Source

02

Grow

03

Harvest

04

Experience

Stem cells can be extracted from anywhere on a living animal. In the case of salmon, cells can also be isolated from their fertilized eggs.

Because of the warming climate and increased habitat destruction caused by dams, deforestation, and development, dozens of subspecies of salmon are on the brink of extinction across the North Pacific.

Most Pacific salmon return to their home streams after 3 years in the ocean. Salmon are a keystone species, meaning they are a species on which other species in their ecosystem depend, and if they decline in population the ecosystem will change drastically.

Step 01

Source

We start with living cells from pristine Pacific salmon. Pacific salmon are found throughout the North Pacific Ocean and in most coastal rivers and streams from Alaska to central California.

We grow our cells in a nutrient blend that creates a nourishing environment, similar to what they'd experience inside a wild fish.

Our cells grow when we feed them the same nutrients fish and humans need to thrive: protein, sugar, fat, salt and other minerals like iron and zinc.

Our cultivators are very similar to the stainless steel fermentation tanks used to brew beer and kombucha.

Step 02

Grow

The innovative design of our cell cultivators creates conditions similar to those within a wild fish. The right temperature, pH, nutrients, and many other conditions help our cells to grow and mature.

Our process doesn’t require fishing boats or fish farms — or any living salmon after our initial sourcing step.

Plant-based ingredients help provide structure and replicate the texture of conventional fillets.

The perfect piece of salmon sushi should have that delicate balance of dense firmness and melt-in-your-mouth fattiness.

Step 03

Harvest

We harvest the cells from our tanks and integrate them with a few plant-based ingredients to help create the flavor, texture, and appearance of conventional salmon fillets.

Today our oceans are more contaminated than ever before. Wildtype salmon is as fresh and cleans as it gets, delivering both peace of mind and exceptional quality.

Wildtype salmon is made in a tightly-controlled environment, minimizing exposure to contaminants that unfortunately can find their way into conventional seafood.

Our sushi-grade salmon can be used in all your favorite raw sushi preparations, from sashimi to maki.

Step 04

Experience

It’s true that our salmon represents innovative science, but first and foremost, it’s just really good fish. We strive to delight every person who tries Wildtype salmon with its pure, delicious flavor and texture.

Nutrition

The cleanest, most sustainable seafood on the planet.

Similar omega-3 profile to wild-caught salmon

Harmful amounts of mercury, antibiotics & parasites

Genuine salmon cells combined with powerful plant ingredients

Environmentally destructive fishing & fish farming practices

Pilot Fishery

We purpose-built our demonstration-scale Fishery in San Francisco to learn everything we can before we begin to scale our production process. This facility looks just like a neighborhood microbrewery, except we grow salmon cells in our tanks instead of beer. We even have our very own tasting room.

Tissue Culture Room

Where we start with just a few cells, selecting the ones with the best traits.

Process Development

Process Development Room

Where we create the starts for each batch, just like you would if you were baking bread or brewing beer.

Process Development

Water Filtration

Cell culture requires deionized water, super pure water that has been treated to remove all ions that make up the dissolved mineral salts.

Growth Tanks

Growth Tanks

This part of our facility looks nearly identical to a beer brewery with rows of large stainless steel tanks for growing our cells.

Growth Tanks

Steam Cleaning

Each tank is sterilized with steam to ensure each culture is pristine.

Growth Tanks

Harvesting

Once a batch is ready, we harvest the cells from each tank and remove excess liquid.

Harvest & Production

Tasting Room

Located in a converted loading dock and equipped with a full sushi bar, "The Dock" is our favorite place to congregate and sample the fruits of our labor.

Tasting Room